Piezoelectric Ultrasonic motor as a Multileaf Collimator drive - Wischnewskyi Ultrasonic Motors

APPLICATIONS

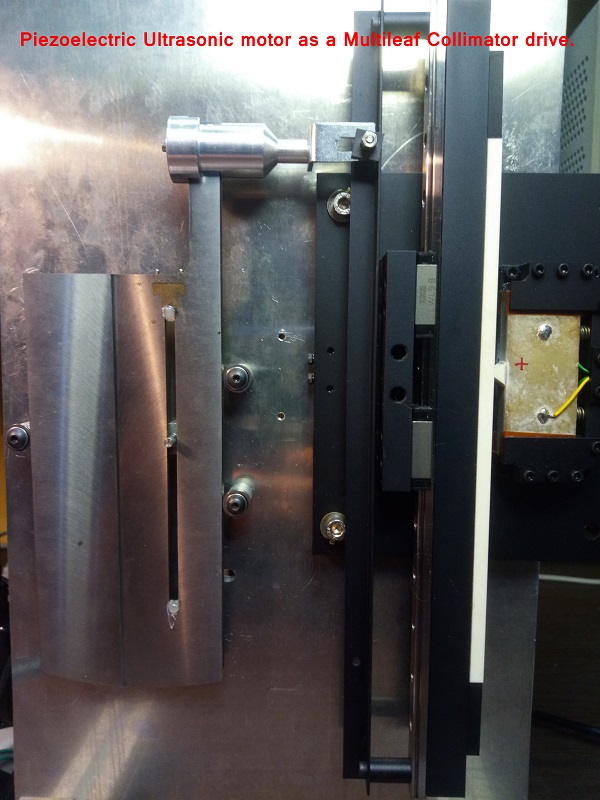

Piezoelectric Ultrasonic motor as a Multileaf Collimator drive.

Cancer is a major disease that afflicts humanity. Nowadays, one of the most powerful methods of cancer treatment is radiation therapy. Radiation therapy or radiotherapy is the treatment with ionizing radiation or an electron beam. At present for cancer treatment medical linear accelerator is widely used. Such a linear accelerator produces powerful X-ray radiation or the flow of electrons of different energies. Modern radiotherapy's purpose is to suppress the tumor without significant damage to healthy tissue. Methods of radiation therapy gradually improved, allowing more and more to cure previously incurable patients. Therefore, research and invention work on the improvement of medical equipment for radiation therapy is relevant to work and so the subject of my Canadian patent is a hot topic and such invention itself opens up a new way to solve current problems in medical devices for cancer treatment. In radiation therapy is very important to treat unhealthy tissues and minimize radiation damage to healthy tissues. The aim of Canadian patent # 2,700,614 is to introduce a new innovative design principle of Multi-Leaf Collimator leaf drive intended to be used in the medical linear accelerator for the treatment of cancer.

All current Multileaf Collimator (MLC) leaf drive mechanisms are electro-mechanical assemblies that still employ conventional electro-magnetic motors with gear mechanisms or drive screws. Therefore, they can suffer from some drawbacks such as mechanical backlash which limits the positioning accuracy. Furthermore, gear mechanisms add additional weight, complexity, and cost to the system. Also, all modern MLC designs using conventional electromagnetic motors require repeated calibration to maintain tolerance. There are many reasons for this situation. First, with a screw-type mechanism to advance the MLC leaf, a certain amount of mechanical freedom, “slack”, must be allowed for the screw to turn. The slack is responsible for mechanical backlash which degrades the system accuracy. Typical MLC leaf position accuracy is about 1-0.5 mm, for example, Siemens 160 MLC, Elekta Agility MLC. The weight of the MLC and its assembly can cause a slight bend in the mechanical system which might lead to mechanical slack. In radiation therapy is very important to treat unhealthy tissues and minimize radiation damage to healthy tissues- that is why MLC accuracy is a very important aspect.

Finally, repeated movement wears the thread, increasing the slack even more. Furthermore, mechanical linkages and gears add complexity and weight to the device and can increase drive overall manufacturing cost. Another drawback of such drives is that the irradiating fields can destroy the electrical insulation of the conventional electrical motor windings. This leads to the possibility of having short circuits in the windings, reducing the operating lifetime and reliability of the motors. Yet another drawback of such designs is that the conventional electrical motors have cobalt iron as a component in their armatures and stators which can become radioactive in the strong radiation fields. Thus, radioactive elements such as Co-57 and Co-60 can be produced and this presents a cost of after-use storage due to the long half-life of these isotopes and related disposal costs and regulatory risks involved if these radioactive motors inadvertently get into the normal waste stream.

Employing ultrasonic linear motors as the drive of the multileaf collimator leaves can eliminate the above-mentioned drawbacks. Wischnewskiy Ultrasonic Motors motors can be used in various types of X-ray machines to drive tungsten plates of X-ray MLC collimators, under the influence of strong X-ray fields.

Here is the video of WUM piezoelectric ultrasonic motor pushing heavy 800 grams MLC leaf against the gravity: