Ultrasonic piezoelectric motor type WUMoRC2-50 - Wischnewskyi Ultrasonic Motors

APPLICATIONS

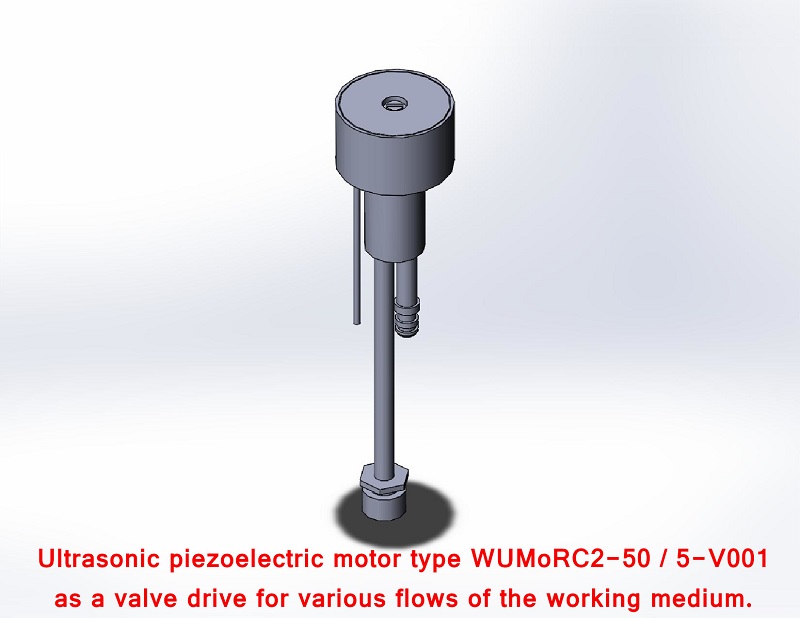

Ultrasonic piezoelectric motor type WUMoRC2-50 / 5-V001 as a valve drive for various flows of the working medium.

This rotary piezoelectric ultrasonic motor WUMoRC2-50 / 5-V001 can be easily scaled and changed to work with another valve or similar device.

This development relates to motorized controlled valves for regulating the flow of any kind of liquid, steam, gas, or vacuum. It consists of a piezoelectric motor type WUMoRC2-50 / 5-V001 and the valve.

This development is intended for use in energy, chemical industry, food industry, municipal economy, etc. The basis of a piezoelectric controlled valve is a piezoelectric rotary motion motor combined with a hydraulic valve. In particular, this is a valve with a valve body and a detachable ultrasonic motor of rotary movement connected to it, which, on the one hand, allows very fast shut-off of the valve, and on the other hand, allows, if necessary, to very accurately regulate the flow of the working medium.

Piezoelectric ultrasonic motor type WUMoRC2-50 / 5-V001.

Motor design.

The design of the WUMoRC2-50 / 5-V001 motor and the principle of its operation was first described in 2001 in patents:

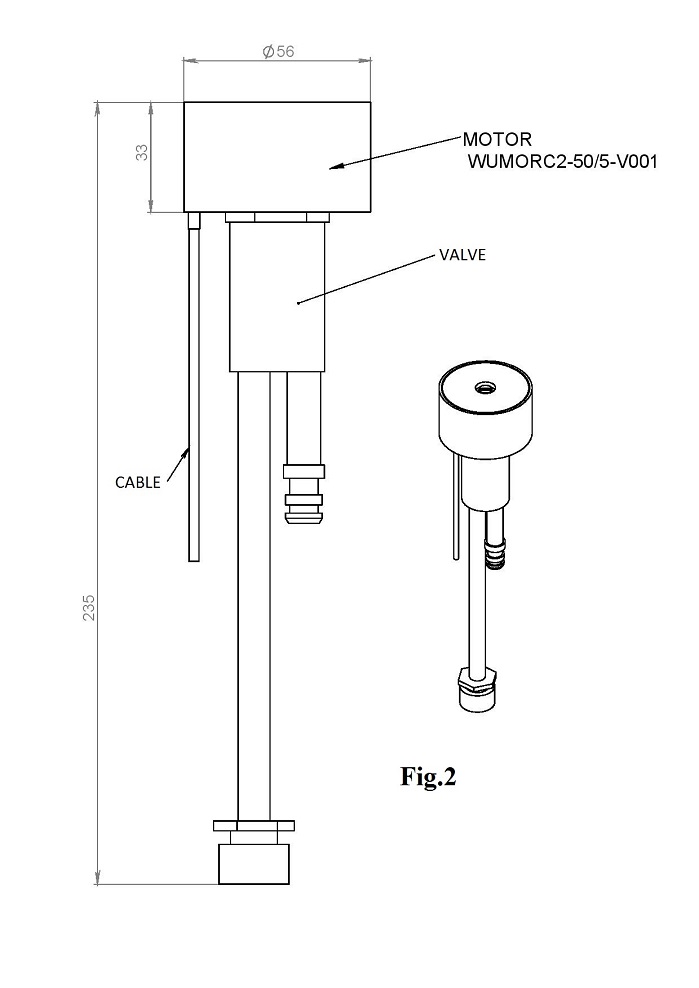

Motor height 35 mm, diameter 56 mm.

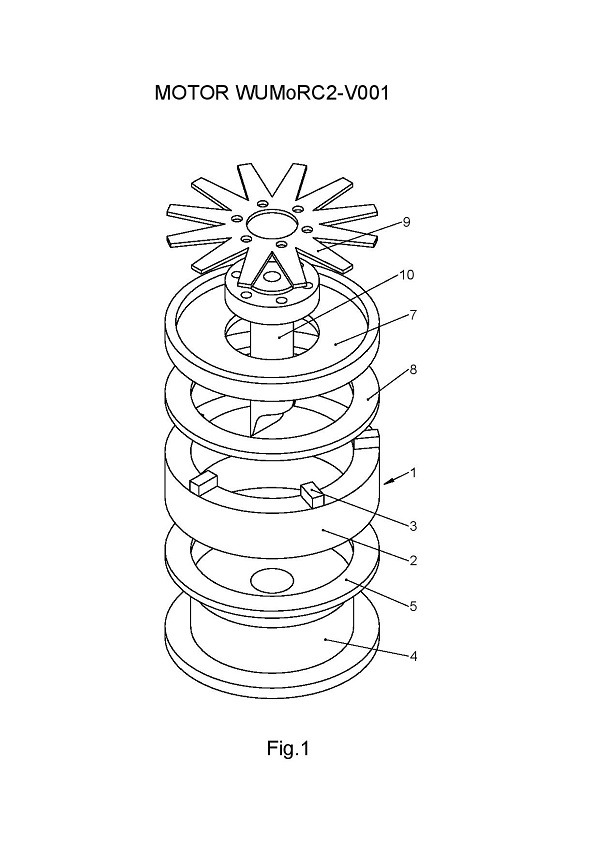

Figure 1 shows a simplified design of the piezoelectric ultrasonic motor WUMoRC2-50 / 5-V001.

The motor contains an annular ultrasonic piezoelectric actuator 1 with a diameter of 50 mm, including an annular piezoelectric element 2 on which friction elements 3 are installed.

An ultrasonic piezoelectric actuator 1 is located on base 4, on a sound-insulating pad 5. The rotor 6 of the motor contains a driven disc 7 with a friction layer 8, a flat spring 9, and a shaft 10. Spring 9 presses the driven disc 7 with a friction layer 8 to the friction elements 4 of the actuator 1.

The principle of operation of the piezoelectric ultrasonic motor WUMoRC2-50 / 5-V001.

The operation of the motor is based on the simultaneous excitation in the annular piezoelectric element 2 of the annular piezoelectric actuator 1 of two standing acoustic deformation waves propagating in two mutually perpendicular directions. One wave is the first mode of a standing longitudinal acoustic deformation wave propagating along with the height of the annular piezoelectric element 2 of the actuator 1. The second wave is the tenth mode of the standing longitudinal acoustic deformation wave propagating along the circumference of the annular piezoelectric element 2 of the actuator 1.

Excitation of both acoustic waves is carried out by an alternating, single-phase electrical voltage through exciting electrodes and common electrodes. For this, the piezoelectric element 2 of actuator 1 contains the first and second groups of exciting electrodes and common electrodes.

When an electric voltage is applied to the first group of exciting electrodes and to the common electrodes, the friction elements 3 move along elliptical paths in one direction. When an electric voltage is applied to the second group of exciting electrodes and to the common electrodes, the friction elements 3 move along elliptical paths in the other direction.

The movement of the friction elements 3 along elliptical paths causes the frictional interaction of the friction elements 3 with the friction layer 8 of the driven disc 7 of the rotor 8. This leads to the rotation of rotor 6 and shaft 10 in one direction or the other.

Motor parameters WUMoRC2-50 / 5-V001.

Maximum excitation voltage - 50 V

The excitation voltage frequency is 129 kHz.

Current consumption at maximum voltage - 0.5 A

Maximum shaft rotation speed - 4 r / s (1400 deg / s)

Maximum torque when braked rotor - 30 ... 35 Ncm

Possible applications of the piezoelectric ultrasonic motor WUMoRC2-50 / 5-V001.

The WUMoRC2-50 / 5-V001 motor is designed to drive various types of taps, gates, dampers, valves, regulators, or metering devices - gases, liquids, or bulk materials.

Example of piezoelectric ultrasonic motor application WUMoRC2-50 / 5-V001.

Figure 2 & 3 shows a piezoelectric ultrasonic motor WUMoRC2-50 / 5-V001 motor mounted on a standard valve.

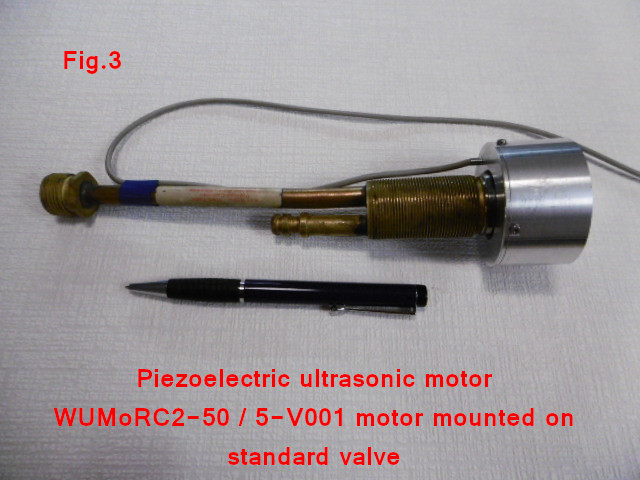

Figure 4 shows a photograph of a piezoelectric ultrasonic motor WUMoRC2-50 / 5-V001 motor mounted on a standard valve with the rear cover removed.

Video 1 shows the operation of the motor, WUMoRC2-50 / 5-V001, mounted on a standard valve with the rear cover removed. The measured braking torque of the valve is 15 Ncm. In the video, the motor periodically turns on and off or changes the speed of rotation of the rotor of the motor by changing the magnitude of the exciting voltage.

The motor operates when the braking torque of the valve force on the motor rotor is equal to 15 Ncm. In this case, the maximum rotation speed of the motor rotor is 840 deg/sec.

Video 2 shows the operation of a motor, WUMoRC2-50 / 5-V001, mounted on a standard valve. The motor is loaded with a standard spring dynamometer which is connected to the motor rotor by a thread through a 20 mm diameter pulley. The maximum force measured by the dynamometer when the rotor is stopped is 15..20 N. This is equal to 15… 20 Ncm of the moment of the load force on the motor rotor from the dynamometer.